LAVICHIP SIMCT406 Bus Series Control System - Application on Precision Insert Manipulators

IMD, also known as Injection Molding Decoration Technology, is mainly used for the decoration and functional control panels of household appliances automotive dashboards, air conditioning panels, mobile phone shells/lenses, washing machines, refrigerators, and other processing processes. It is widely used. Products previously made with coating technology can achieve unprecedented visual effects after switching to injection molding technology, giving people a refreshing feeling. Injection molding for in mold inserts is a comprehensive application technology that integrates printing, molding, molding, and injection molding processes, combined with plastic sheets, ink, and plastic resins.

1. Case background:

A simple overview of the in mold insert is the production process of placing a component into the mold cavity for injection molding and then removing it. It refers to the injection molding process of pre placing metal, plastic, and other components into the mold for injection molding, and integrating them with plastic to form a new component.

2. Process difficulties:

So what technical difficulties will arise in terms of procedures and processes? A: Applied to injection molding machine internal inserts, the system controls the vibration disc feeding, inserts, and takes 4 copper parts separately, requiring high-precision alignment with a repetition accuracy of ± 0.05mm. B: The conventional use of a regular robotic arm+PLC control for feeding can be cumbersome and costly, requiring simultaneous operation on both sides during wiring and startup. In response to this situation, Langyuxin adopts a bus type control system to ensure the movement accuracy of the robotic arm. The subroutine parallel control of the feeding device saves time,and the separate system control eliminates the trouble of interactive wiring. A single system saves customer costs.

LAVICHIP Solution - SIMCT406 Robot Control System

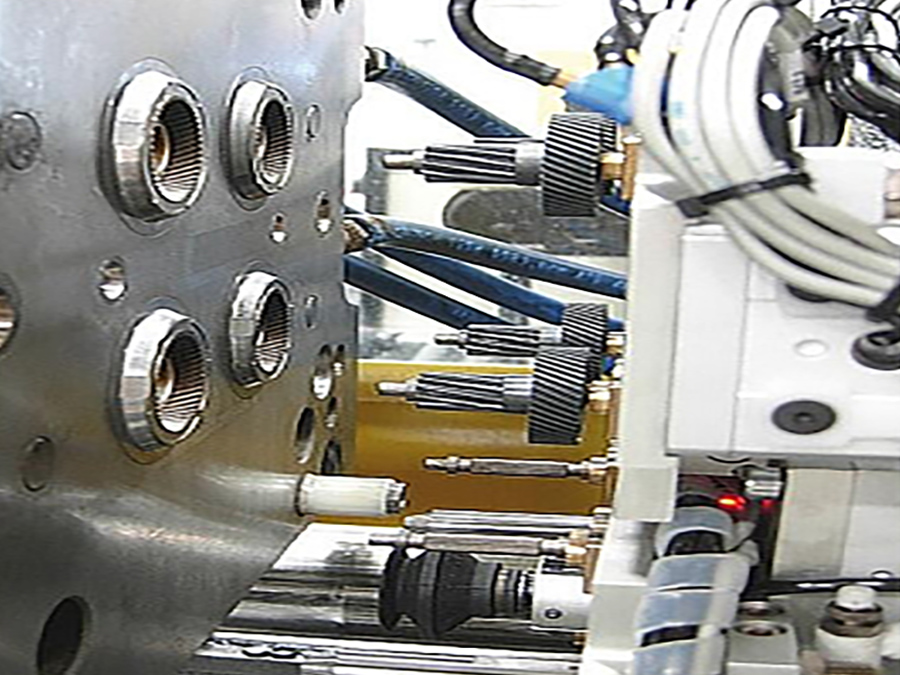

The SIMCT406 bus series of LAVICHIP control system is widely used in precision insert models. The control system is equipped with

HT0804 manual control, CIMC06-2 motherboard, AIMC20 IO board (optional), as well as servo drivers and execution components. It is equipped with programmable professional software,

which has high scalability and supports user secondary development.

1. Program features:

Integrated and simple precision insert control system, cost-effective solution; High precision, high-speed multi-step point operation with repeated accuracy less than 0.2mm; Low jitter, optimized stable operation control algorithm.

2. Scheme architecture:

3. Product features:

The LAVICHIP robotic arm control system has the characteristics of reliable quality, stable operation, simple debugging, and convenient

maintenance in the injection molding robotic arm industry. For the injection molding robot industry, LAVICHIP has provided timely services and excellent product cost-effectiveness. With 15 years of deep cultivation in the industry, Langyuxin has a deep understanding of motion control, and has a greater influence

on the application of control systems in the injection molding robot industry. With highly innovative technology, integrated application solutions,

and comprehensive after-sales support services, Langyuxin has won the trust of customers.

Our Advantages:

1. Professional product solutions

The SIMCT406 bus series can meet the high-precision alignment requirements of the insert in the mold, abandon the traditional method of

manipulator+PLC system, and use more professional motion controller to achieve the process standard of complex processing.

2. Efficient technical algorithms

Flexible teaching and easy operation. Compared to traditional wiring and startup, it is troublesome to operate simultaneously; LAVICHIP

uses a bus control system and flexible algorithm configuration to improve the operational efficiency of the robotic arm.

3. Stable and reliable products

The product adopts a modular structure, which is easy to assemble, supports secondary development, has strong universality, and is

convenient for customer standardized management.

4. Rich industry applications

Successfully applied in batches in different industries and models, gaining high recognition from customers.