The Application of LAVICHIP CLACT306 Bus Manipulator Control System on Double Z-axis (Two Dragged Two) Truss Manipulator

1. Case background:

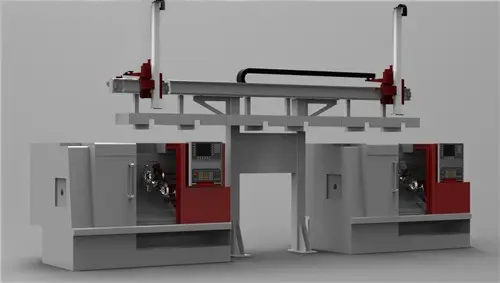

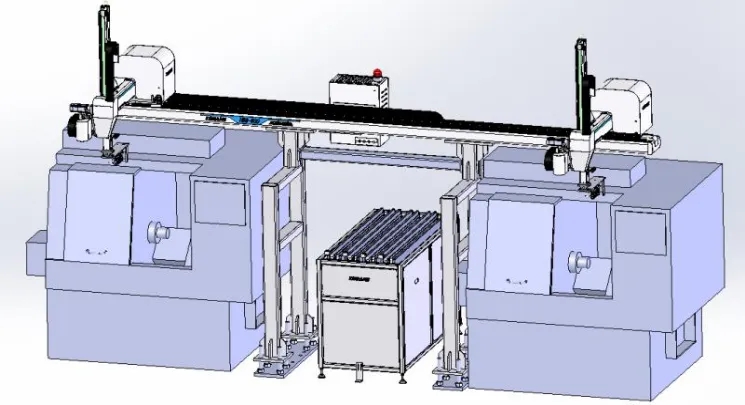

Truss type robotic arms are widely used in automated production lines, such as CNC CNC lathes and CNC machining centers. They automatically complete loading and unloading of materials for processing, thereby reducing labor costs, improving production efficiency and quality. The dual Z-axis (two dragged two) truss manipulator has high requirements for control system algorithms and technology, ensuring that the mechanical arms operate independently and do not interfere with each other. Due to the need for more complex processing with multiple machine tools, it is often not possible to use an independent single arm robotic arm. It is necessary to coordinate and work in parallel with multiple arms to complete up and down material retrieval, thereby saving hardware costs and meeting real-time process requirements.

2. Technical difficulties (for a certain process):

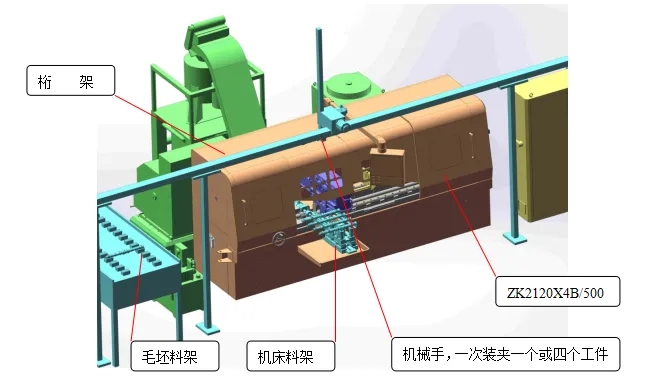

A: Lathe loading and unloading process, applied to small lathes to pick and place processed workpieces, replacing manual automation

B: The conveyor belt silo is layered with partitions, achieving automatic retrieval and placement of three-dimensional silos, reducing customer complexity in silo tooling design, and equipped with stacking technology,

C: Standard stacking, one group for material retrieval, two groups for material placement, three groups for partition separation between subroutines,and four groups for finished product partition separation. After completing one building, use subroutines to feed the entire pile and stop after sensing in place.

LAVICHIP Solution - CLACT306 Bus Series

LAVICHIP has launched the CLACT306 bus series, equipped with HT0803 manual control, CLAC06-2 motherboard, AIMC20 IO board (optional), as well as servo drivers and execution components. Equipped with programmable

professional software, it has extremely high scalability and supports user secondary development.

1. Program features:

·High precision motion control algorithm, accurate positioning, small error, with anti-collision protection, absolute value positioning and other functions;

·The LAVICHIP CLACT306 series supports CANopen bus control technology, with high efficiency and low cost;

·Supports CAN bus IO expansion modules, with a maximum of 16 IO modules expandable and flexible;

·Developed application processes for the lathe industry to meet different machine models and application needs;

·The appearance layout is reasonable and beautiful, with industrial grade structural design that conforms to ergonomic operation methods;

2. Scheme architecture:

Typical Configuration Table:

Our Advantages:

Professional product solutions

LAVICHIP has launched the CLACT306 bus control system to meet the needs of complex machining between multiple machine tools.

It is equipped with an HT0803 manual controller, CLAC06-2 motherboard, and AIMC20 IO board (optional) as an overall solution, supporting 9

axes and 7 expansion boards.

Leading technological algorithms

Internally, there is multithreading technology, logic and jump technology, flexible teaching, and simple operation. The combination of loading and

unloading processing function with dual arm and dual control, combined with powerful algorithm calculation and flexible configuration capabilities,

makes the robot operate more efficiently and interact faster.

Stable and reliable products

The product adopts a modular structure, which is easy to assemble, supports secondary development, has strong universality, and is convenient for

customer standardized management.

Rich application experience

Successfully applied in batches in different industries and models, gaining high recognition from customers.